Nitrogen fertilisers have long been the cornerstone of modern crop production. They’re essential for delivering the yields we depend on. The process by which nitrogen fertilisers are made hasn’t changed over the years. Technologies have improved efficiencies and helped to reduce the emissions associated with nitrogen manufacturing.

Currently, fertilisers and manures account for around 2.6 gigatonnes of CO₂ emissions globally each year. Of this, nitrogen fertilisers contribute more than half the carbon footprint of cereal crops. Roughly 28% of these emissions come from how we apply fertiliser in the field, while the other 28% comes from manufacturing.

The key process behind nitrogen fertiliser production – the Haber-Bosch process, developed in the early 1900s – hasn’t changed much in over a century. It creates ammonia from nitrogen in the air, natural gas (methane), and water (steam). While efficient for producing fertiliser, it uses a lot of energy and generates large volumes of carbon dioxide.

But new technologies are offering farmers more sustainable options:

- Grey ammonia, the most common type, is produced using fossil fuels.

- Blue ammonia uses the same process but captures and stores the CO₂ produced. This method uses carbon capture and storage (CCS), sequesting CO₂ produced during the manufacturing process.

- Green ammonia is the cleanest option. It uses renewable electricity (solar or wind) to split water and create hydrogen through a process called electrolysis, which is then combined with nitrogen from the air to make ammonia – all without relying on fossil fuels.

These latest technologies don’t compromise on crop performance. You’ll still get the same nitrogen content and uptake, but with a much lower environmental footprint. For example, switching from standard ammonium nitrate (which produces around 3.4 kg CO₂e per kg of N) to green ammonia-based products can cut emissions by up to 50%.

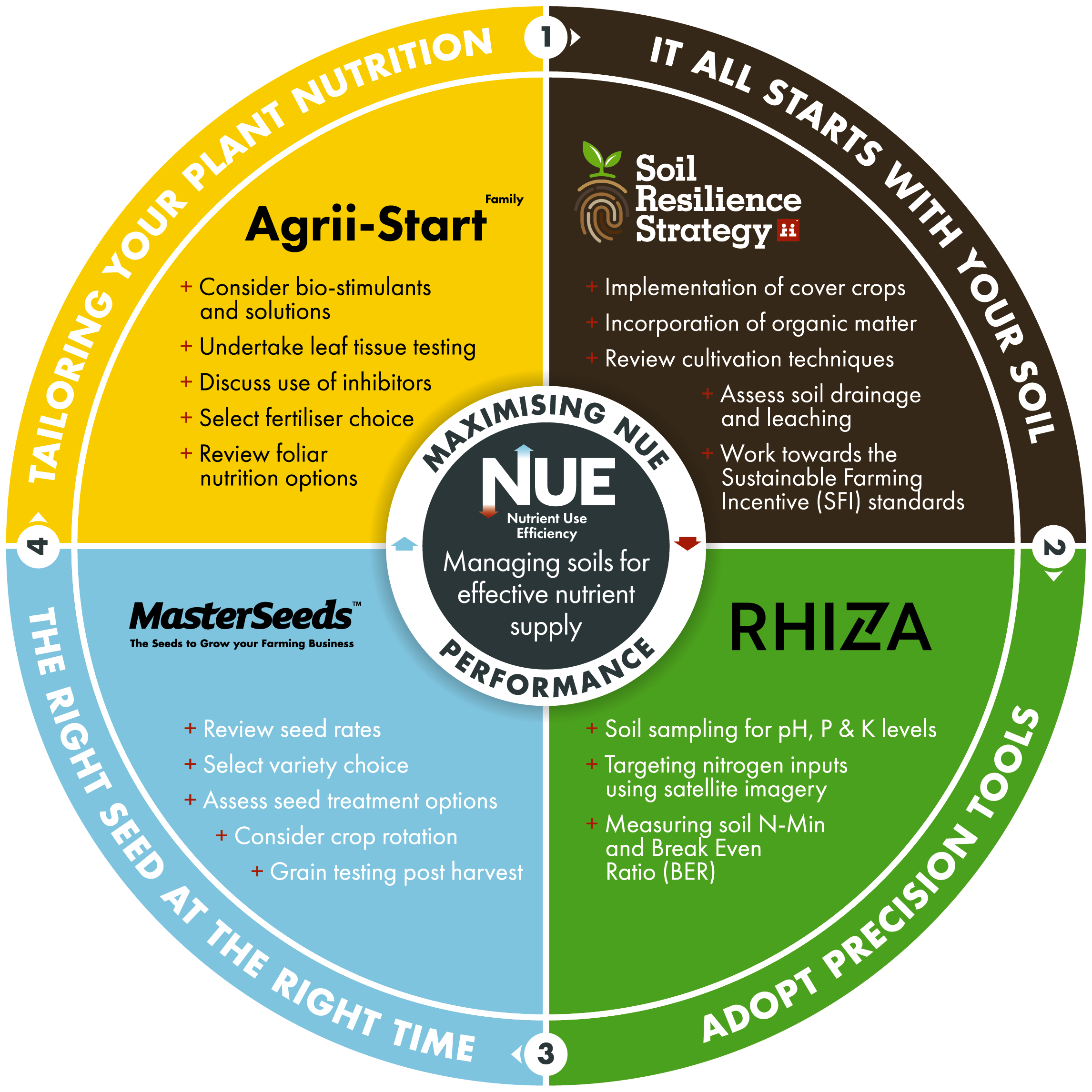

Agrii is actively investing in research and partnerships to improve Nitrogen Use Efficiency (NUE) and support growers with more sustainable fertiliser solutions. The goal is to reduce in-field losses and support practices that help meet emerging carbon standards.

There’s a growing market interest in low-carbon farming. Using these new fertiliser types can help farms access carbon credit schemes, reduce exposure to future carbon taxes, and meet buyer requirements for greener produce.

Change is coming – and it’s a chance to improve both the farm’s environmental impact and long-term profitability. The fertiliser industry across Europe has committed to becoming carbon neutral by 2050. With the right tools and choices today, UK growers can stay ahead and benefit from that transition.