Huntapac’s parsnip crop, grown without human machinery operation, used Skippy Scout drone monitoring operated by Agrii’s technical experts in the world’s first instance of entirely autonomous vegetable agronomy and production.

Huntapac, in collaboration with Autonomous Agri Solutions, AutoSpray Systems and Agrii, funded by the Marks and Spencer Plan A Accelerator Fund, successfully grew a crop of parsnips autonomously. This achievement is believed to be a world first.

The field-scale trial is the most recent step in a series of trials investigating how to improve the sustainability of Huntapac’s carrot and parsnip production, says Stephen Shields, technical and sustainability director at Huntapac.

“We have done a lot of work looking at low-carbon fertilisers. We started doing 80 acres and have expanded that to 1,700 acres this year.“

This work has been combined with an autonomous field concept, which is when Agrii and the other partners became involved. It coincided with Marks and Spencer launching the Accelerator Fund to discover innovative technologies that will enable its rapid progress towards becoming a net zero business across its supply chain by 2040.

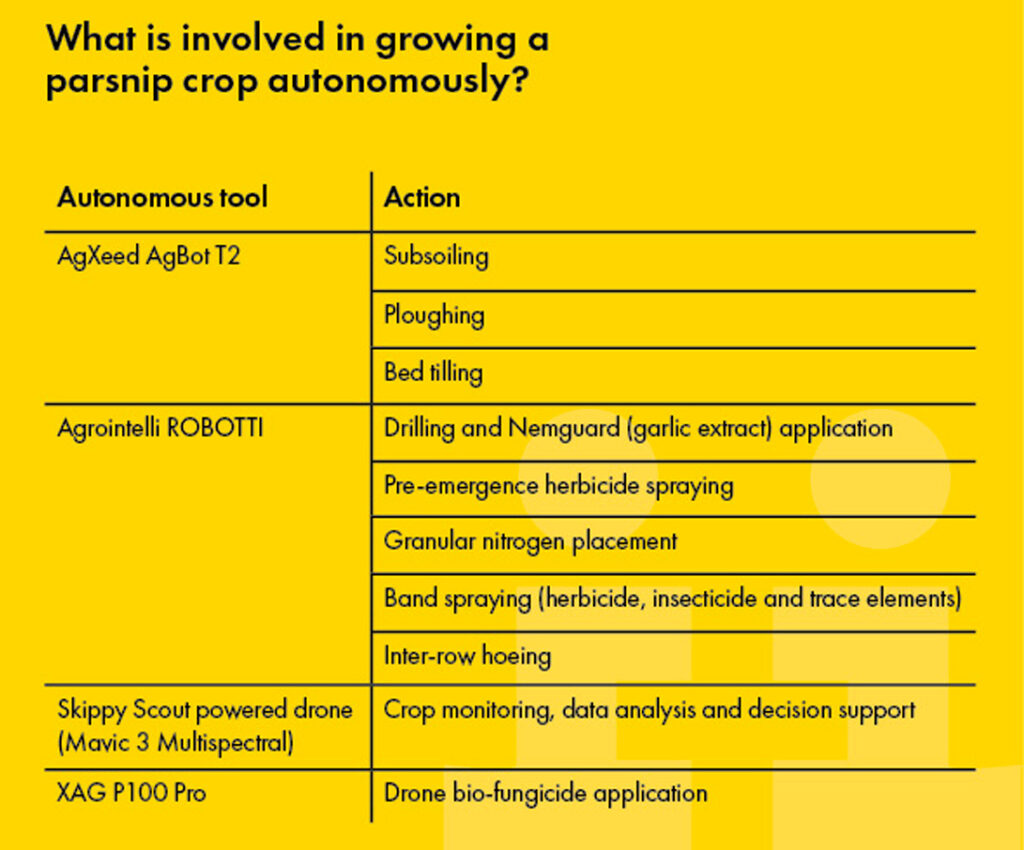

To prepare the field, an AgXeed electric drive autonomous tractor was used for primary and secondary cultivation, says Tom Beach of Autonomous Agri Solutions.

“That was able to do the subsoiling operations and ploughing, which was the first case of autonomous ploughing in the UK. Finally, it did the bed tilling.

“A Robotti was utilised for the following lighter operations. We use this because it has a standard three-point hitch to use conventional agricultural implements, but it is substantially lighter and more accurate than a tractor.“

The crop was drilled using a single-bed Stanhay X-Series drill, comparable to what is used in a conventional tractor pulled triple-bed drill. Tom believes that the longer work hours possible using autonomous technology means that smaller-width implements will deliver at least the same efficiency as larger human-operated ones.

The Robotti was responsible for the weed control, spraying the pre-emergence herbicide across the entire bed width. Subsequent applications were made post-emergence using a band sprayer on the rows and an inter-row hoe between them.

The project called on AutoSpray Systems’ expertise in drone spraying for variable rate and selective biopesticide and fertiliser applications. Robert Pearson, CEO of AutoSpray Systems, explains that the technology is well-equipped for the precise application of pesticides.

However, what drones can apply is limited by regulation because plant protection products approved for use in parsnips need specific approval for aerial application. Most biopesticides and fertilisers can be applied through the drone system, says Robert.

Autonomous vegetable agronomy

To monitor the crop and guide the precise application of plant protection products, Agrii used a drone equipped with Skippy Scout to do the agronomy.

Skippy Scout is a software system that will automatically fly a drone to selected points in a field and send high-resolution, leaf-level images to aid with decision-making. The system analyses the captured images and sends a field report, explains Jonathan Trotter, technology trials manager for Agrii.

He used a drone to collect data from the field every few weeks. Parsnips were not a crop that Skippy Scout was working with before the project. “That’s a really nice element of the project; we’re developing the AI in the background to use Skippy Scout in parsnips going forward.

“We’ve reported back to the group every time we have surveyed the field. The idea is that we can then deploy the other technologies accordingly,“ explains Jonathan.

“Skippy Scout helps identify the areas to be treated, which can be inputted into our app to treat those areas specifically,“ says Robert. “We’ve been asked if our (spray) drones can do the same level of crop monitoring, and our response is absolutely not. That’s where Skippy Scout is a perfect solution.

“We believe this method will allow conventional chemistry to remain on the market for longer because you apply much less of it using our precise process. At the same time, it allows us to apply more novel products much more easily.“

Robert used the drone to apply bio-fungicides to the crop for disease prevention. This is a task a drone is especially well-suited to because the airflow from the propellers agitates the canopy, giving excellent leaf coverage for the bio-fungicide.

Scaling digital interoperability

The successful field-scale trial has demonstrated a 46% reduction in carbon emissions and significant labour and input savings. Naturally, thoughts move to how the system developed by the group can be rolled out on a larger scale.

Interoperability between the systems controlling the decision support tools and machinery is a crucial milestone. This is a challenge Agrii has already begun working on.

“We are integrating Skippy Scout with our digital platform, Contour,“ says Jonathan. “This can then be linked to soil mapping through Rhiza, and further into the future, it could export treatment recommendations to the other technologies used within this very project.“

Tom Beach says the sprayer on the Robotti is already equipped and ready to do this. “It has the standard Topcon ISOBUS, giving us full variable rate capability. We can input field maps or shape files, whatever the source is.“

The data could originate from an agronomist or decision support system like Contour. As well as applying variable rates across the sprayer’s width, Robotti can be programmed only to treat specific areas and return ‘as-applied’ data through its Crop Eye camera.

More precise digital record-keeping will benefit Huntapac’s relationship with its suppliers, says Stephen Shields. “The request from our customers is to have full electronic traceability throughout the process. For some, that’s from 2025.“

Tom concludes by saying that regardless of the ag tech’s sophistication, external factors like the weather and soil conditions will still dictate how the crop is grown.

“As much as we can automate the sensing and recommendations, we are a long way from removing a human from the decision-making process.

“Robots will do whatever you tell them, but knowing what to tell them still requires a huge amount of skill.“